Offset Absorption: Adding Arsenal to Armament

Considering the volume of defence expenditure planned in the 11th Five Year Plan and in the future, it is certainly befitting for each recipient service to debate methods and procedures that offset this expenditure and contribute towards the economic and technological development of the country.

Over several years offsets have grown in importance; have found favour; and gained currency amongst arms importing countries. India has identified the great promise that offsets afford since expenditure on acquiring armament could now add to the arsenal; both through development of armament related industries and through other related / unrelated industry; balance of trade payment; generate employment; develop niche technologies; and, in some small or large measure achieve all these objectives. India has recently formulated an offset policy framework for defence procurements. After studying various models, India has adopted a gradual, incremental and phased approach for offsets in defence procurements. This policy is reviewed periodically and two such reviews have already been undertaken. Therefore, it is indeed opportune that we are today discussing a road map to see how and with what effect the offset policies can be put into operation and what outcomes and value addition can accrue to Indian industry without causing additional obstacles to the procurement process.

To begin with, India has taken a policy decision to incorporate a clause for seeking offsets on all defence imports of value exceeding Rs 300 crores, as Direct Offsets only. The paper covers the following broad issues:

- Key Concepts and Ideas.

- Stakeholders, Categories and Options.

- IN(Indian Navy)-offsets: Values and Volumes.

- Offset Absorption – Plans and Approaches.

Key Concepts and Ideas

There should be complete clarity on what offsets must achieve and also what they must not. Offsets must accomplish well thought out and well defined strategic or economic objectives. The defence industry, worldwide, is uniformly not a perfectly competitive industry and with technology control regimes as well as other non-tariff barriers to trade which distort the arms market significantly every arms trade transaction is somehow unique. Given this scenario, countries tend to extract for themselves the best terms of contract, and contract negotiation is quite often based on relative bargaining skills of the buyer and the seller. The bottom line is that we need to exercise caution and discretion against attractive offset offers that could detract the buyer from the main objective of the purchase and instead chase the red herring offset at the cost of the quality and price of the required equipment.

A second important consideration is not the type of offset in terms of quantities but its value as a quality product of high technology or service that must be accorded primacy in evaluating offset proposals. It must contribute towards developing niche technology in specific sectors, develop indigenous capacity and promote domestic defence industry but it must not be seen as a simple balance of payment issue. Since acquisition goals of the services are driven by operational considerations, which are time bound, therefore, in the process we need to guard against the pitfall of laying more than required emphasis on offsets to the detriment of the acquisition programme itself. Finally, offset offers must of course be supported by the principle of value for money.

Stakeholders, Categories and Options

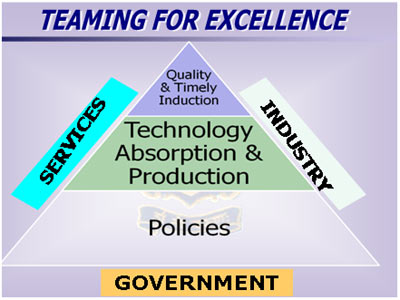

It is well known that there are three prime stake holders in offset programmes. Firstly, the Government must lay down the policies for compliance by the Industry and the Services. Industry must be able to absorb the offered offset offer and deliver the requisite production capability to the international offset partner. The Services seek quality and timely induction. Hence, offset proposals would need to be balanced in such a way that the end result is a win-win-win situation for all three stakeholders. This is depicted in Fig 1 below:

Figure 1

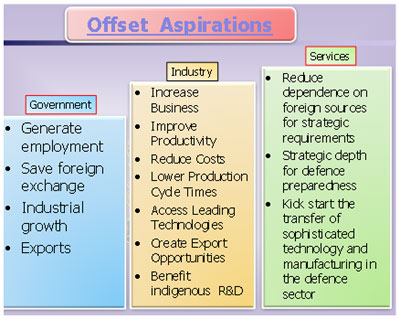

It would be apparent that the aspirations of the three stake holders could be different and if not at conflict certainly in competition with each other. These are tabulated at Figure 2 below. The success of an offset programme would lie in maximizing the aspirations of all three stakeholders. Theoretical tools, drawn from welfare economics such as the concept of Paretto optimality and Nash Equilibrium can indeed be applied to each proposal but that would be a subject by itself. At this stage not mathematical modeling but objective value judgments should steer the offset discussions. A cooperative rather than a competitive approach between the three stakeholders could maximize benefits. However, true value would only be forthcoming if the Government takes industry into confidence before processing the acquisition programme and certainly before the Request for Proposal (RFP) has been issued. This would enable a long term strategic approach to realize the benefits of offsets as a planned activity.

Figure 2

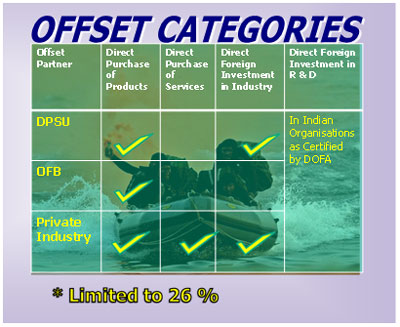

Categories and Options

There are several categories and options for availing offsets. So far as the categories are concerned, they can be broadly divided into technology, products and services. The options for partners are limited to DPSUs (Defence Public Sector Units), OFB (Ordnance Factory Board) and Private Industry. Figure 3 correlates the offset categories and partnership option. What is interesting to note here is that Direct Foreign Investment in R&D has now been included in DPP-2008 but only in those Indian Organisations certified by the Defence Offset Facilitating Agency (DOFA).

Figure 3

Worldwide, the usual mechanisms for offsets can be broadly classified as sub contracts, equipment and machinery purchases, co-production, technology transfer and license production. Of these, Transfer of Technology (ToT) remains the most popular and usually preferred type of offset the world over, especially for countries that aspire to build an indigenous defence industry. In an analysis, it emerged that up to 30 per cent of all offsets provided relate to technology transfers. Statistically, transfer of technology is needed the most popular and preferred type of offsets the world over. 16 per cent of all offsets provided by U.S. companies have been towards technology transfers. By and large, nations see technology induction through the offsets route as a stepping stone to develop indigenously more advanced technologies than was transferred. One example, that is often quoted, refers to the success of the aeronautics industry in Brazil where aviation technology in both the military and civil sectors have synergized effectively, producing a world-leader in the regional short haul jet market.

Successful technology transfer requires some well defined underlay. Firstly, the transfer of technology must be economically valuable. Secondly, there must be institutional capacity and a knowledge base available within the buyer country to absorb superior technology smoothly. Thirdly, such transfers must be without any restrictive conditions attached. Inclusion of a restrictive condition should be combated in any offset contract, particularly those that do not include the know-why components of a ToT proposal, for example, source codes for IT products. Technology transfers should be sought by indigenous Defence Industry only if such transfers can be subsequently self-sustaining through in-house value addition and innovation to create a more superior next generation product. Only then can the local defence industry become self-sustaining and avoid obsolescence. Singapore is an example of the successful implementation of a niche based technology transfer offset policy. Therefore, technologies sought as a part of offsets package must be clearly spelt out at the Request for Proposal stage of the procurement process itself, after due consultation with industry and indigenous R&D centers. However, whilst a centralized Offset agency has been created in the form of DOFA at the Ministry of Defence, coordination with industry through CII / FICCI / ASSOCHAM / NASCOM and the industrial R&D base including academic institutional research carried out at IITs, is somewhat loose ended as a single window facility is yet to be created or if it exists then it requires greater publicity. The danger is that unless there is coordination at the apex level, technology offers can be duplicated, as say in the case of aircraft inductions which are based on civilian airframes, avionics and engines, resulting in less than optimal gains from the offset process.

As far as category of offsets is concerned, this paper is limited to discussing issues of obtaining technology as offset options. In India technology transfer is not an option for offsets. Firstly, it is contended that latest technology is never on offer since a host of export control laws are imposed by the vendor country upon the buyer which actually escalates the commercial value of the technology transfer proposal without commensurate benefit. Secondly, there is the difficulty in measuring the real impact and effectiveness of the ToT. Consequently, a critical aspect of technology transfer is its valuation. In any such evaluation, the differentiation between the cost of a product and its value to a buyer needs to be noted. Mathematically, a model using economic theories such as utility theory and rational choice theory can possibly throw up some methodology for objectively evaluating the cost and benefits of technology transfer of cost specific production. Despite these drawbacks this paper argues that ToT should be included as the foremost options for offsets.

However, it is important that an integrated approach is followed to evaluate the best benefit. The indigenous industry capacity to absorb technology, the state R&D infrastructure to develop such technology further and the national Human Resource base needed to do so must all be holistically synergized if technology transfer is to succeed. All cogs of the offset process must indeed be meshed if the offset machinery is to move. This is shown in Figure 4 below:

Figure 4

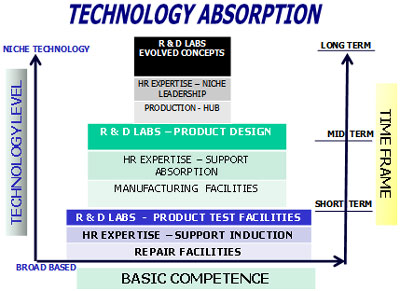

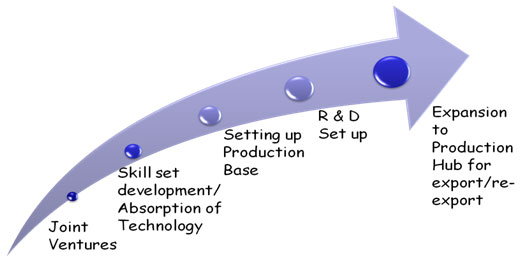

Technology absorption should only be sought in sectors where some degree of basic national competence and international competitiveness already exists. This is the foundation upon which the technology absorption strategy is to unfold. As a model it could begin with an integrated approach of setting up appropriate specialized institutions that nurture, develop and expand HR skills that can support the induction of such technology initially. This must be simultaneously supplemented with establishment of R&D Labs that can test products and establishment of manufacturing facilities at the sub assembly level. Thereafter, developing HR skills that support absorption of technology, improving the R&D infrastructure to the product design level and manufacturing facilities at the component level can be established. Subsequently, the niche advantage can only accrue if industry develops a production hub at the regional level, develops the HR leadership in that specific niche technology which is supported by world class R&D Labs that has the potential to develop patents in that particular sector to finally assume global leadership in that specific niche product.

Such a model clearly brings out that if technology absorption is to succeed then isolated and superficial transfer of technology only to industry will not serve the national objective of offsets. Unless complementary HR issues such as development of specific scientific expertise and commensurate manufacturing technology is also imbibed no real and long term benefit from costly offsets would accrue. A model for technology absorption through offsets is depicted in Figure 5 below.

Figure 5

Multipliers in Offsets

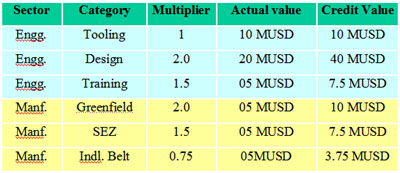

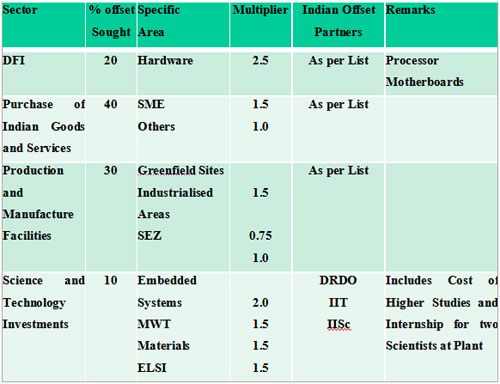

A second issue addressed in this section is the issue of Multipliers. Buyer countries today, provide “multipliers” to offsets that provide technology that they critically require or even investments in sectors that need Foreign Direct Investment. Multipliers are additional credits over and above the market value of the technology or product or service offered. It is for the buyer to ensure that sufficient information is available to vendors to formulate offset packages that closely meet the buyers’ specific technology requirements.

Multipliers are defined as additional mechanisms to offset offers that serve a specific highly defined purpose or an economic objective. These multipliers act as an incentive for foreign vendors to offer offsets which requires them to spend least capital and human effort and yet meet the offset obligation efficiently in a product or sector in which the buyer has interest. This is achieved by applying multipliers to the actual value of an offset offer to provide a larger credit value to the vendor and thus reflects the buyers’ targeted preference in deriving specific benefits from the offset proposal. Thus, credit value may be more or less than the actual value depending upon the multipliers determined by the buyers. Multipliers in offset offers have not yet been introduced in the offset policy in India.

In the Indian context also, offset proposals that provide enhanced benefit in a desired area which could be technology, economy or industry needs to be considered. Figure 6 below illustrates the broad concept of multipliers. For example, offsets in the engineering design sector attract a multiplier of two and therefore whilst the actual value of the offset obligation may be 20 MUSD the credit value would be 40 MUSD. Similarly, manufacturing facilities established in green field areas would attract multipliers of two whilst setting up the same facility in an industrial area would only allow a multiplier of 0.75, thereby reducing the 5 MUSD actual values to a credit value of only 3.75 MUSD. Consequently, the credit value could change as depicted in Figure 6 below. In this way, i.e. if multipliers are introduced in the offsets policy the percentage value of offsets can rise beyond 100 per cent.

Figure 6

Reports state that buyers who demand high percentage of offsets are also liberal with multipliers. This is apparent since both vendors and buyers can benefit by following a higher credit value of offsets with multipliers which can be leveraged for future transactions. Both vendors and buyers may also benefit from reduced offset management costs by concentrating on fewer offset contracts offering higher multipliers. Therefore, to meet an offset obligation of say 100 MUSD both vendors and buyers may prefer a single contract of an actual value of 25 MUSD but with a multiplier of four rather than several small value obligations with multipliers of one or less.

Mechanism for Implementing Offsets

Vendors have certain mechanism for meeting offsets obligations. These include sub-contracts including for services, equipment and machinery purchase from Indian Industry, co-production of assemblies, sub-assemblies of components sourced from Indian industry, license production through use of fully formed / semi knocked down or completely knocked down units. In the process of production some amount of technology, limited to know-how rather than know-why, is imbibed through unstructured osmosis to an Indian vendor. However, there are other sectors where offsets can be sought. These relate to repair and overall facilities either at the inspection level or at the deep level, manufacturing and production of spares and components, establishment of design and testing facilities and investment in research and development activities which could be either product specific or technology specific.

Seeking product specific offsets has certain advantages. Here again the formative principle must be to ensure long term benefits and not just transient business opportunities. In the manufacturing sector, high technology components and product with assured markets and which, in the long term, can help in creation of a production base that can meet the regional if not global demand should be sought. Similarly, in the service sector, offsets should result in value added services particularly in the finance, outsourcing and software development sector. Meeting offset obligations in the service sector is a fairy difficult proposition since valuation of the offsets offer is difficult to bench mark against the services offered. However, since the service sector is manpower intensive, offsets obligation in this sector could result in larger employment generation and specific skill creation.

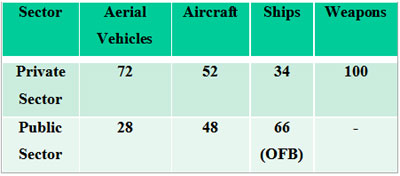

IN-offsets: Values and Volumes

Approximately Rs 22,500 crores worth of naval acquisitions are planned in the 11th plan which would attract the provision of offsets. If indigenous industry has not evolved then an almost similar amount can be anticipated to be available in the 12th Plan also. It is, therefore, imperative that the opportunity that offset obligations foreign vendors provide must be leveraged to the best advantage of the state. If this opportunity is to be fruitfully exploited, then an offsets absorption plan for the short, medium and long-term should also be conceived, discussed with Industry and approved by the Government. In one word a consolidated and comprehensive approach needs to be in place for the offset programme to genuinely succeed.

Aerospace, Shipbuilding and Development of Systems are the key sectors in which offsets would be generated for the Indian Navy. The aerospace sector has a potential of about Rs 6500 crores in offsets, the ship building sector has a potential of about Rs. 6200 crores and high technology weapons and sensors have a potential value in the range of about Rs. 1600 crores. All in all, business worth anywhere between Rs 6500 crores and 11000 crores is expected to be generated through the Offsets Route, if the planned schemes fructify.

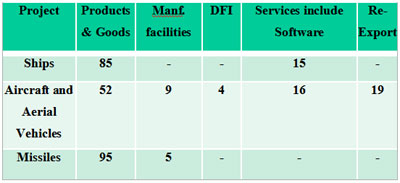

Figure 7

The first naval case involving offsets was the acquisition of the Fleet Tanker for which the contract was signed in April 2008. Many valuable lessons pertaining to offsets were learnt while negotiating the deal and a need was felt to have a coherent and cohesive offset absorption plan in place if the full benefit from the provisions of offsets in future naval acquisitions were to be derived. These plans are being prepared for the short term, mid term and long term. The Indian Navy, since the inception of the offsets provisions of the DPP, has negotiated four offsets in the sectors of shipbuilding, aircraft and aerial vehicles and missiles. The broad pattern of the offsets obligations, by percentage value, is depicted in Figure 7 below:-

A Vision and Objectives

As mentioned earlier, for offset programmes to be beneficial for national development, a clear vision and an enunciation of policy objectives is necessary. A possible vision statement for the Navy with regard to offset absorption could be “To achieve global leadership in specific technology, products and services in the maritime sector by leveraging offset opportunities which arise through induction of foreign equipment and systems.”

From this vision statement the fundamental objectives of the offset absorption plan can be enunciated and these could be summarised as follows:-

- To access, absorb and amass expertise in sophisticated niche technologies and products.

- To develop HR resources that support specific niche technologies.

- To develop an export / re-export base for domestic industry in defined technology sectors.

- To develop comparative advantage in production and marketing of specific maritime applications products.

- To obtain lifecycle support for the purchased product and the opportunity to re-engineer the same after incorporation of innovations and improvements in design.

- To reduce the foreign exchange component of naval Capital procurements.

- To leverage arms purchases for benefits in “other” sectors by way of counter trade, linked purchases or obtaining concessions in various negotiations.

- Offsets in academic research programmes at IITs and other such institutions.

Offset Absorption Plans and Approaches

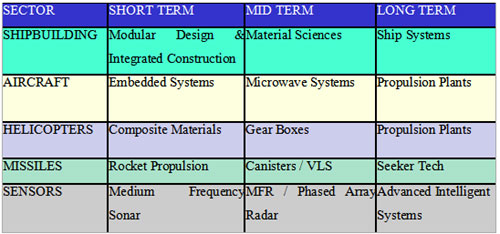

Broadly speaking, Offset Absorption Plans can be categorised into `Product Specific’ and ‘Technology Specific Plans’. Within each of these two categories, Short Term, Mid Term and Long Term goals can thereafter be set. Irrespective of the category, the overall aim of the offset absorption roadmap is to attain global supremacy both in the specific technology as well as the product.

Utilising Technology specific offsets would require identifying sectors and attract investments in state-of-the-art technology such as nano-technology and material sciences etc, that, in the long term, provide a competitive advantage in producing niche products. This could be in conjunction with the DRDO which could render advice on the preferable technologies for seeking offsets, since DRDO has the domain knowledge on the degree of defence technology available in India and also has information on the critical requirements of the future. Similarly, the Department of Defence Production has the domain knowledge on the potential of the Indian industry and could identify firms that could absorb the manufacturing technology in a particular field. Also, it is not sufficient to identify the specific technology or competence that it is sought to be developed but at the RFP stage itself it would be appropriate to indicate to potential vendors the prioritisation that India would seek in offset offers. An indicative methodology is as shown in Figure 9 below. Therefore, identification of the priority areas where technology transfer is to be sought would be the first task and subsequently the same would be stated upfront in the RFP itself.

Figure 9

Five core sectors for utilising technology-specific offsets can be identified. These would enhance the nation’s manufacturing and production capability in the sectors of industry that is of interest to the Navy. Offsets could effectively be utilised to create or modernise repair and overhaul facilities for ships and aircraft and even various equipment and their sub components. Development of dual use technology is another core competency that could be developed. Design, research and development in niche technology areas in which competitive advantage can be created or accentuated is another vital sector for utilising offsets. Close cooperation with DRDO, Department of Defence Production and Industry will be needed for identification and implementation of technology specific offsets. Associated with the induction of technology would be the establishment of laboratories, simulators and testing facilities which are essential for strengthening the Research and Development base and the development of HR skills and expertise.

Developing technology or setting up production facilities are alone not sufficient to ensure global supremacy. There is a need to develop HR skills concurrently to absorb and develop niche technology. Induction of manpower and their training for the highest levels of utilisation of technology and production is an activity whose importance cannot be over overlooked and must form an integral part of the offset absorption plans. An example that is often quoted is that of Turkey which negotiated a package for two personnel to train as Astronauts with Boeing. A graphical representation of the various milestones envisioned while utilising offsets is shown in Figure 10 below.

Figure 10

The precise time frame required for completing various activities related to absorbing offsets would be different for every acquisition case involving offsets. While this is being laid down at the project level, various key activities need to be also identified for accomplishment in the Short Term, Mid Term and Long Term. Some of these are illustrated in Figure 11 below.

Figure 11

Product Specific Offsets – Some Examples

As far as Product Specific Offsets are concerned, these would aim at developing the capability for manufacture of niche products such as Missile Homing Heads, Actuators, Gyros, Radars, certain components of high technology systems, Rocket propulsion materials, Turbine blades, crankshafts to name a few. Products taken up for manufacture through the offsets route must however be those with substantial demand and an assured market in the long term. Induction of technology would then be accompanied by the setting up of a ‘Production Base’ which would be expanded progressively to become a `Production Hub’.

Beginning with naval aviation, Figure 12 below provides an illustration of the specific products that are required to build up the indigenous industry to world class standards.

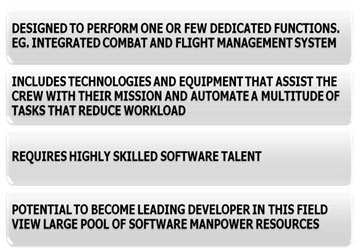

Figure 12

Microwave technology is useful in developing intelligent and sophisticated modern air borne combat systems and applications include Electronic Surveillance Measures (ESM), Radar, and EW Jammers, etc. Such technologies also have COTS application in field of RF / Microwave Technology. The point is that there is already some experience with DRDO, and only an incremental investment in capabilities would need to be augmented by developing commercial entities. Offsets in this area would support in transitioning COTs technology into military / naval requirement. So far as embedded solutions are concerned some features are depicted in Figure 13 below. Again this is a niche technology area and expertise development would provide long term competitive advantage to the Indian aviation industry.

Figure 13

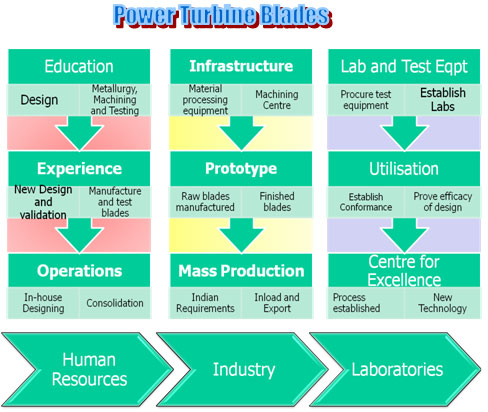

From the shipbuilding sector an example is Power End Turbine Blades of Marine Gas Turbines. Whilst Indian industry and the R&D establishment do have some inherent competence in manufacturing Marine Gas Turbines, a core area where competence and expertise does not exist is in the sector of Power End Turbine Blades. Figure 14 below depicts how a well planned offset strategy can develop this expertise in India.

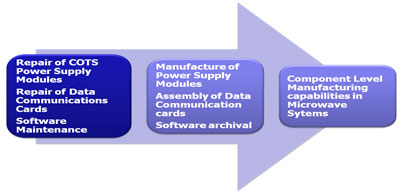

Similarly, another area where due lack of a specific expertise a world class competence in the manufacture of generator sets has not been achieved is the fabrication of crankshafts for heavy duty continuous rating mega Diesel Engines. Figure 15 below indicates a Model for absorption of offsets in a generic manner and the example that it refers to is in the case of microwave systems.

Figure 14

Figure 15

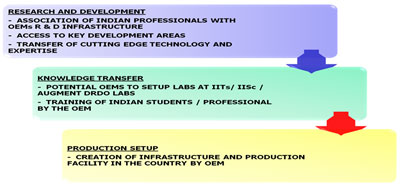

Action towards such a Model would be mandatory to develop a three step process that integrates Research and Development, knowledge transfer and subsequent specific manufacturing and production including test facilities. Figure 16 below depicts a process that could be adopted to facilitate this objective.

Figure 16

Conclusion

One of the most important methods of policy implementation is project management. As a discipline, Project Management developed from several different fields of application, including military projects, mechanical engineering, and construction activities. Like any undertaking, projects need to be executed under certain constraints.

Traditionally, these constraints have been listed as: scope, time, and cost. With the onslaught of globalisation, all sectors of indigenous economies worldwide have become extremely competitive, more result oriented, structurally lean and technologically sophisticated. The room for error is undoubtedly less and this calls for extremely sensitive and adept handling of projects that must meet the specified scope of the project in the allotted time and budgeted cost. Even adherence to these stipulations may not satisfy governments if they suspect that chances for higher productivity in project implementation have been overlooked by the project management team. In order to derive the benefits of the Offset Policy, successful implementation of the offset policy is of paramount importance. It, however, needs to be emphasized that implementation of the offset policy involves a learning experience for both the buyer and the seller, and solutions will evolve as we work on our offset programmes.

In essence, this paper suggests that policies are not sufficient by themselves to achieve the full benefit of offsets and unless policies are supplemented with a clear vision, specific objectives and a well articulated strategy, piecemeal and fragmented offset proposals will be the order of the day. This would be sub-optimal returns on a rather significant investment.

To conclude, it is significant to reiterate that the value of an offset depends primarily on its appropriate selection, implementation and monitoring. Ill-conceived and ill-planned offset programs invariably prove to be highly wasteful in national resources and uneconomical in value. Further, offsets should not be viewed in isolation as one-time agreements, but as an important and integral element of a long-term national policy.

In summation, the key recommendations of the paper are:

- Formulation of a National Offset Vision which factors in :

- Requirements of the Services.

- R&D Capabilities including Laboratories and HR resources.

- Existing and Forecast Industrial Capacity.

- Economic Objectives.

- Change from Vendor Driven to Buyer demanded Offsets:

- RFP to specify desired Sectoral preferences in offset propositions.

- Direct Foreign Investment sought in specific industries and targeted areas.

- Purchase of specially identified goods and services from the SME.

- Creation of definite manufacturing and co-production facilities in Greenfield areas.

- Specific technologies that are to accompany offset investments and the multiplier that

- such technologies and sectors of investment would provide.

- Multipliers as incentives for offsets in priority areas:

- Targeted locations.

- Specific industrial products.

- Niche technologies.

- Provide for more than 100 per cent offsets.

- Consideration for Industry

- Offset sales to be deemed exports.

- Encourage SMEs.

- Guarantee assured markets for co-developed products after offset absorption.

| Attachment |

|---|

Download Complete [PDF] Download Complete [PDF] |