Leveraging Defence Offset Policy for Technology Acquisition

Offset provisions were promulgated by Ministry of Defence (MOD), Government of India in DPP-2006 [1], and revised in DPP 2008 [2]. These provisions are applicable to all Capital Acquisitions categorized as ‘Buy (Global)’, i.e., outright purchase from foreign / Indian vendor, or ‘Buy and Make with Transfer of Technology’, i.e., purchase from foreign vendor followed by Licensed production, where the estimated cost of the acquisition proposal is Rs. 300 crore or more. A uniform offset of 30 per cent of the estimated cost of the acquisition in ‘Buy (Global)’ category acquisitions and 30 per cent of the foreign exchange component in ‘Buy and Make’ category acquisitions is the minimum required value of the offset. A dedicated body ‘Defence offset facilitation Agency’ (DOFA) has been set up under DPP, MoD as a single window agency mainly to facilitate the implementation of the offsets policy and assist potential vendors (OEMs) in interfacing with the Indian Industry. Banking of offset credits has been also introduced in DPP-2008. Foreign vendors could consider creation of offset programmes in anticipation of further obligations. Offset credits so acquired can be banked and discharged against future contracts.

India is one of the largest arms importers in the world. Its defence imports which at present stands at $5-6 billion per year, is expected to grow further. It is estimated that in the 11th plan period, business worth $10 billion would be generated through the offset route. Utililisation of this purchasing power by leveraging offset provisions to achieve the national aim of self-reliance in design, development and production of Defence systems is a challenge for the entire country. All stakeholders involved in the development and production of defence systems e.g. Department Of Defence R&D, Services and Indian Industry need to synergize to achieve this National objective. Prioritizing the areas for leveraging offset investment flow is essential for meeting this National challenge.

In this paper the authors discuss why acquisition of critical technologies and specialized facilities is accorded highest priority for leveraging offset investment flows.

What is ‘Technology’ and why it is important?

Technology means different things for different people and is also defined differently by different people. Therefore, it is important to define ‘Technology’ in the first place and then look at its importance. The National Academy of Engineering (NAE) defines:

“Technology includes all the infrastructure necessary for designing, manufacture and repair of technological artifacts- engineering know-how, manufacturing expertise and various technical skills – all or equally important part of technology”

Therefore technology is not just products. It is a combination of Science and Engineering. Science aims to understand the “Why”, Engineering is design “under constraint” with science being the main limiting factor. Therefore, technology is all encompassing. It involves design, drawings, code of practices, engineering standards, data sheets, raw materials, manufacturing processes, software, test procedures, test equipment and above all implicit knowledge resident in human resources.

“Technology is power and will continue to be so in foreseeable future” says Dr. R. Chidambaram PSA to GOI. Those who control the technologies, control the world. The western world fully understands the power of technology and hence tries to control the flow of technologies through control regimes.

Technology is so important because acquiring critical technologies has following advantages:

- Enables design, development and production of systems across the platforms.

- Many related and unrelated applications of some technology can be derived.

- May trigger development of a set of new technologies.

- Enables our industries to handle subsequent product upgrades, provide life cycle support indigenously.

- Enhances technology base in the country.

Why not contract and get ‘Technology’ instead through offsets?

Critical defence technologies are either denied or controlled through various control regimes. These are never offered and therefore can never be obtained through RFP route even when we are ready to pay.

Often it is not the companies that are really worried about transferring the technologies to the developing world but actually their governments stop them from doing so by denying licenses, approvals, etc. MTCR, ITAR, EAR 99 lists are a few mechanisms that are currently used to deny such technologies.

Past experiences show that exorbitant pricing of critical technology modules and denials for various reasons have made many systems not available when required.

Therefore, often it is not possible to get the technology through contracts and leveraging our purchasing power through offsets proves to be the only sure way for acquisition of denied technologies.

Kelkar Committee Observations: International experiences and possible lessons

Kelkar committee in its report [3] has devoted one chapter on International experiences in acquisition of Defence Material in some of the major weapon producing countries and possible lessons for India. The countries covered in the report are U.K, Australia, Israel, France, South Korea and USA. Israel, Republic of Korea (ROK or South Korea) and Australia are of specific interest to us as USA, UK and France are already militarily developed Nations (Permanent members of UN Security council). These countries have shown tremendous progress in defence preparedness in past few decades. The relevant excerpts from Kelkar committee reports about these countries are as follows:

Australia: “Defence (Ministry) administers several complementary programmes that encourage participation of Australian industries in Defence business, promote R&D, facilitate technology and skills transfer from overseas and support defence exports – consistent with the nation’s interest.”

Israel: Emphasis is on acquisition of Technology and not the product.

South Korea: Government stress is to maximize indigenous production, diversify defence supply and acquire as much technology as possible with priority to military related technologies including state of the art technologies.

From these excerpts, it is evident that these countries are vigorously pursuing to get technologies into their countries through offsets.

Past Indian Experiences

All the past experiences related to Technology Acquisition actually pertain to Transfer of Technology (ToT) in real terms. Kelkar committee observations regarding the characteristics of Indian ToT model is as follows:

- Confined to only DPSUs & OFs.

- Depth of technology transfer not adequate.

- Essentially transfer of drawings and processes for manufacturing and assembly and no real transfer of technology. Adopting TOT model for manufacture of imported equipments through License manufacture has not been a success e.g. HAL Fighter Aircraft, BDL Antitank Missile, BEL Fly Catcher Radar, OF T72 and T90.

- No flow of Technology as the MK-II versions or next generation systems never came out of these facilities.

- Dependence on OEMs for upgrades has only increased and not decreased. The above points definitely prove that ToT model is not suitable for meeting national aim of self-reliance in design, development, Production and life cycle support of indigenous defence systems.

Global success stories: Israel, South Korea and China are three major countries which have tremendously benefited from their offset policies.

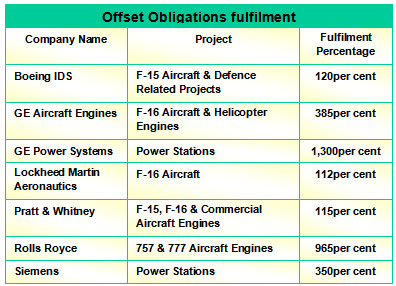

Table 1

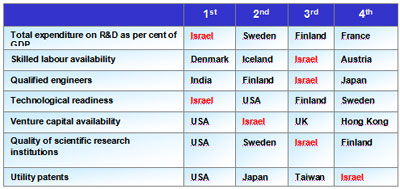

Table 2

Table 3

It is evident from tables [1-3], that Israel even though has much less number of qualified engineers; it is number one in terms of Technological Readiness. It has a large number of successfully fulfilled offset obligations [4], where the Percentage Fulfilment is much more than 100 per cent. As a direct impact of Defence R&D investments in Israel, the country moved from a non-entity amongst Defence suppliers 10 years ago with US $ 900 million per annum today.

South Korea: The focus of the offset policy is on acquiring high technology manufacturing and exporting parts and components. In line with its focus on acquisition of technologies ROK – Ministry of National Defence (MND) reformed [5] its acquisition process in 2001. Under the new provision – the foreign contractors is required to provide assurance in advance that the proposed technologies will be approved for transfer to ROK prior to the approval of the offset contract.

China: Chinese firms have used their leverage to extract offsets agreements to transfer some of the aircraft production along with related expertise and technology [5] as part of the deals. It is one of the most aggressive countries in pursuing offsets agreements and with its market potential and minimal labour standards; it has substantial leverage in negotiating the agreements. China recently announced that it would be entering the large civilian aircraft industry and much of the success of their efforts depends on the transfer of production technology from other countries presumably in the form of outsourcing and offsets from the US and other Aerospace companies. The moot point here is that when China can leverage offsets agreements for Technology Acquisition, why cannot India?

Identification of Critical Technologies and Specialized Facilities

In order to leverage offsets for technology acquisition, we need to know what critical technologies and specialized facilities (not already existing in the country) are required. Authors have suggested a representative set of technologies and specialized facilities as listed below:

Missiles

- Uncooled FPA Seeker for PGMs

- Multi Disciplinary Design Optimization

- Optimal / adaptive control systems

- MEMS based Dual Mode Seekers

- MMW based Imaging Seekers

- High Temp Aero-structures

Aeronautic

- Airframe Shape Optimization

- Re-configurable control system

- Multispectral Data Fusion

- Multiband Flexible Conformal Antennas

- Adaptive / Optimal / Model Reference control

- Thermal Barrier Coatings

- Manufacturing of Single Crystal Turbine Blades

- Surge Margin Improvement (Casing Treatment) in Gas Turbine Engines

- High Accuracy Direction Finding (HADF) using Phase Interferometer (1 Deg)

- Aerodynamic Design and Shape Optimization for Aerostats

- Autonomous landing, take-off and navigation for UAVs

- Smart Aero-structures

- Airframe engine integration and optimization for supersonic aircraft

- Aero Data Prediction Package “Digital DATCOM”

Materials

- SIC / SiCr technology

- Ultrahigh temperature ceramics such as ZrB2 / ZrC / SiC for leading edges

- Development of high hardness steels, Ti alloys, Al alloys and advanced ceramics such as B4C and TiB2

- Gun barrels

- Metal matrix composites

- Ultrahigh strength steel

- Light weight ballistic materials.

- Phase change materials

- Carbon and inorganic nanotubes

- Carbon nanofibres and nanocoils

- Metallic – W, Nb, Ta, Ti alloys and structures

- Non Metallic – Composites / MMC / Multifunctional materials

- Polymers

- Chemicals – Radar absorbing materials

- High Energy Materials

- Nano-materials

- Endothermic fuels

- Propellants and explosives

Naval Systems

- Super Caveat Technology

- Pump Jet Propulsion

- Non-Acoustic Detection

- Active Vibration Control

- Air Independent propulsion Systems

Life Sciences

- NBC Defence Technologies

- Underwater Escape System for depths greater than 100metres

- CNT based Sensors

- MIP based Sensors

- MEMS based Sensors

Specialized Facilities

- High Enthalpy facility

- Hypersonic Wind Tunnel

- Free Piston Shock Tunnel

A probable procedure is to plan and conduct a two day workshop involving users, CIDS and DRDO to evolve a list of critical technologies of national importance fulfilling a specified list of criteria. Countries / Companies who own these technologies can also be listed along with. technical note on each of these technologies, their significance and applications should also be added. Based on the workshop’s deliberations on the above list of critical technologies a national level list can be generated and forwarded to MoD for including in RFPs of major purchases.

DRDO’s views on the Offset policy

- Obtaining Technology: Offset should not be seen as a mere defence trade. All manufacturing activities offered as offset must involve manufacturing of high Technology Defence products rather than products “any one can do.”

- Civil infrastructures: Conventional general purpose equipments and machineries that can be easily sourced from open market should not to be allowed as part of offset. However, special test facilities and equipments that cannot be easily sourced / procured may be allowed as part of offset.

- Leverage large purchase power of the country to acquire Technologies to save time and effort.

- Technology should get into Indian Industry with access to MoD. It need not be into Government entities but allowed to disseminate throughout.

- Technologies into Government Organizations only in cases where industry is not in a position to invest / absorb should get in all such cases provide full access to industries for exploitation.

- Commercialization and exploitation (civilian spin-offs):

- The urge to excel in a competitive environment and exploit the technology to spin-offs is inherent in Private Industries;

- Private industries can also negotiate better with OEMs to get maximum access to technologies;

- DRDO can facilitate in identifying critical technologies and also potential industries which can absorb the technology offsets successfully;

- DRDO to participate in the Technology absorption process to ensure totality and comprehensiveness. This is essential to attract and retain high end manufacturing into the country. Establishing research centres for joint task in academic environment also need to be considered.

Costing of the Technologies: It is difficult to arrive at a figure for each of these technologies. It is time variant, depending on the country and opportunities perceived by the suppliers and value of the main contract. Still an estimate can be made which can be used during techno-commercial evaluation of various proposals.

Conclusion

In brief, leveraging the large purchasing power through offsets is an established method to procure the denied technologies and specialized facilities into the country in relatively shorter times.

| Attachment |

|---|

Download Complete [PDF] Download Complete [PDF] |